Products Categories

Feature Products

Factory Direct Sales High Quality Single Layer Roof Machine

This single-layer machine produces lightweight corrugated board, using 30% less material. Equipped with 11-18 adjustable rollers, it processes pre-coated, galvanized, and aluminum sheets with thicknesses of 0.3-0.8 mm at speeds of 8-12 m/min. The optimized H-beam frame (300-400 mm) ensures structural efficiency for residential projects worldwide, from Scandinavian cabins to tropical bungalows.

Machine Video

Machine Specification

|

No.

|

Item

|

Details

|

|

1

|

Suitable to process

|

Color steel plate, galvanized sheet, aluminum coils and etc.

|

|

2

|

Width of the feeding material

|

914-1250mm

|

|

3

|

Roller station

|

11-18 rows or custom as customer’s requirements

|

|

4

|

Thickness of feeding material

|

0.3-0.8mm

|

|

5

|

Productivity

|

8-12m/min

|

|

6

|

Rollers’ material

|

45# steel

|

|

7

|

Diameter of shaft

|

70-80mm

|

|

8

|

Voltage

|

380V, 50Hz (support customized)

|

|

9

|

Wall thickness of main forming machine

|

12-18mm steel plate

|

|

10

|

Main forming machine body

|

300-400 mm H steel

|

|

11

|

Motor power

|

4-7.5 kw

|

|

12

|

Weight

|

About 5-15T

|

|

13

|

Custom

|

According to customer’s requirements

|

Machine Features

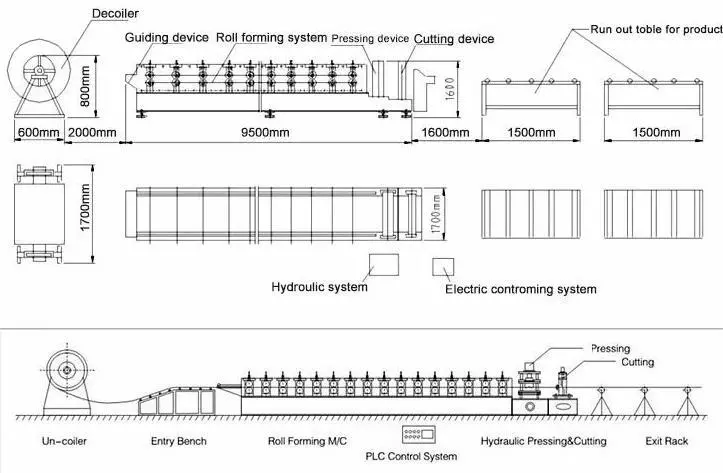

The Working Flow

Manual uncoiler—feeding device—rolling form—speed, length, pieces set by PLC—hydraulic mold post cutting—collection table

Packaging Type Of Bag

Machine Function

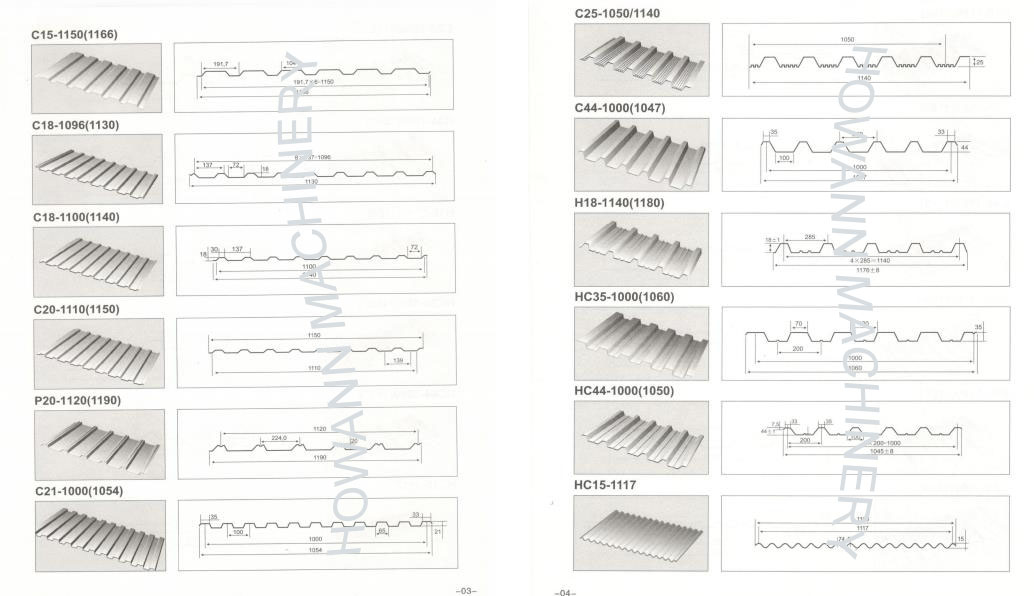

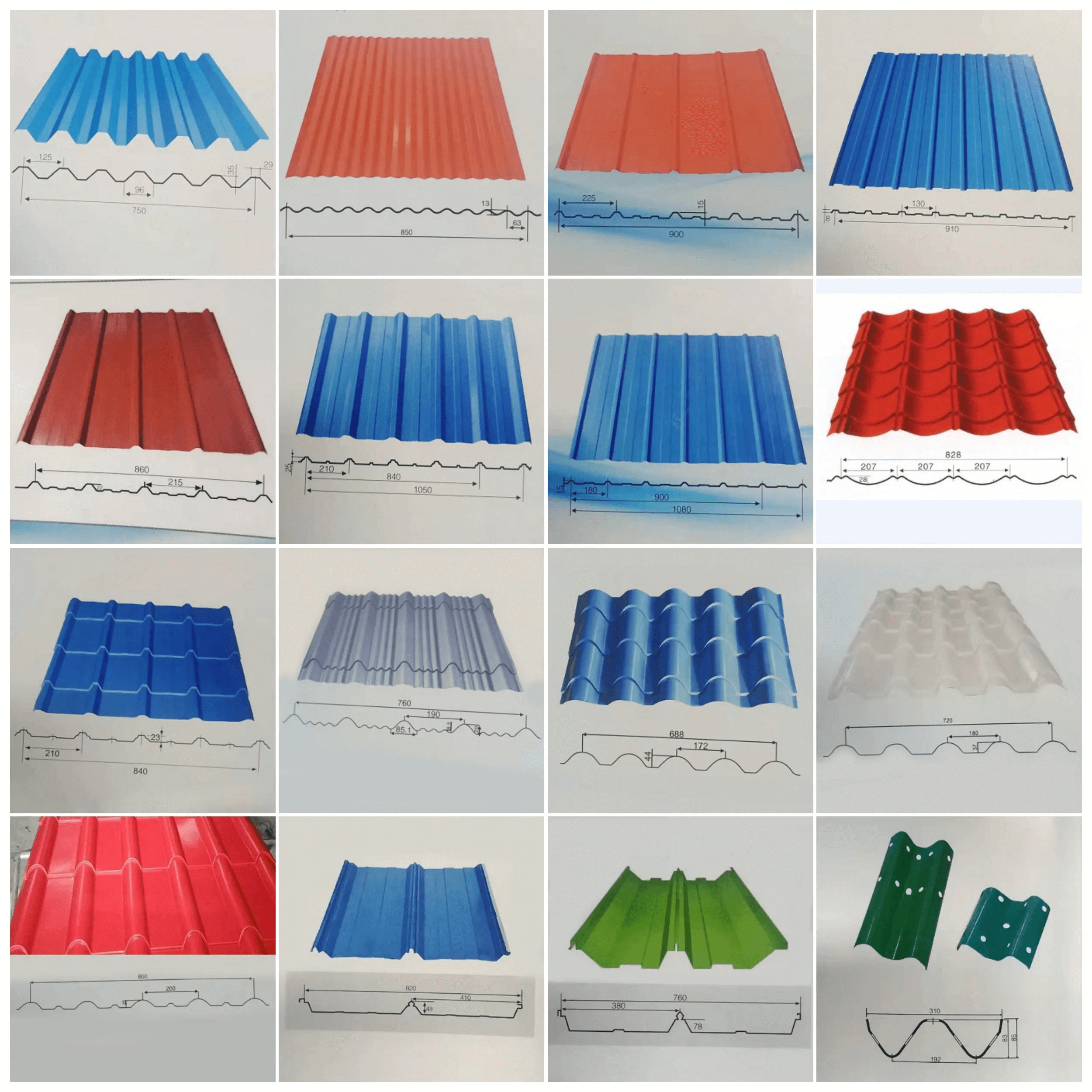

Roof tiles can be applied to the construction of houses in different countries, with a wide range of applications and a bright market prospect. We have a lot of experience, with different layout designs, there is always one that meets your needs. As a professional forming machine manufacturer.

Customized designs are acceptable.

Machine Option

Machine Application

Related Products

CONTACT US

Featured Categories

Contact Us

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

© Copyright – 2003-2023 : Zhengzhou Howann Machinery Co., Ltd All Rights Reserved.