Small error good operation.

Products Categories

Feature Products

Factory Direct Portable Bemo Tile Roll Forming Machine

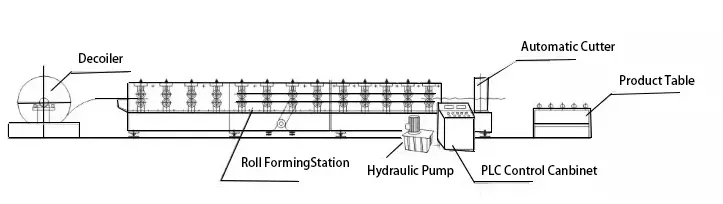

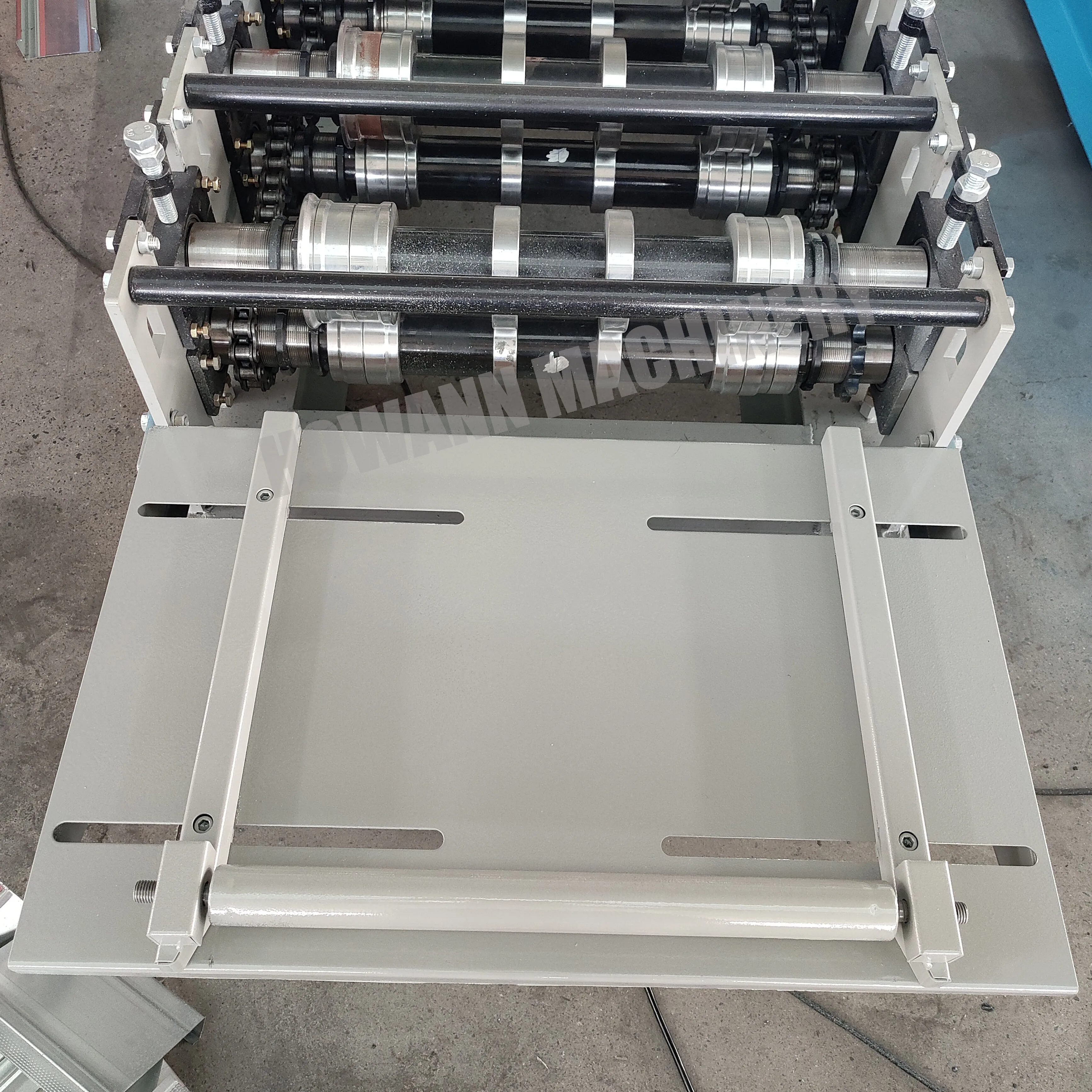

This portable, factory-direct machine, featuring PLC automation, produces standing-edge Bemo metal sheets for on-site construction. Its compact design features 12-14 high-grade forged steel rollers, processes steel and aluminum sheet thicknesses from 0.3 to 0.8 mm, and includes hydraulic cutting and an adjustable feed system. It’s ideal for both residential and industrial roofing projects.

Machine Video

Machine Specification

|

Product name

|

Standing Seam Roll Forming Machine

|

|

Main motor power

|

4kW/5.5KW/7.5KW or as actual demands

|

|

Hydraulic motor power

|

3kW/4KW.5.5KW or as actual demands

|

|

Voltage

|

380V/ 3 phase/ 50 Hz (or as your requirements)

|

|

Control system

|

Automatic PLC control system

|

|

Feeding thickness

|

0.4-0.5mm

|

|

Cutting method

|

Hydraulic cutting

|

Machine Features

Packaging Type Of Bag

Machine Function

Small error good operation.

Material of the roller: High grade No.45 forged steel

Roller station: 12-14 rows

Machine Option

Machine Application

Related Products

CONTACT US

Featured Categories

Contact Us

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

© Copyright – 2003-2023 : Zhengzhou Howann Machinery Co., Ltd All Rights Reserved.